|

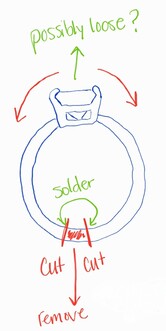

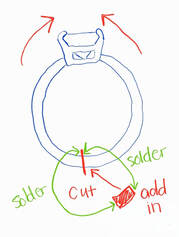

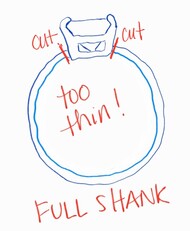

We get this question nearly every day. How do you size a ring? Well, the lucky thing is - I'm not the one who is sizing it! Thank goodness. You would want a real professional! So, we go to our head jeweler, a Jewelers of America Certified Master Bench Jeweler, Jim Rogers. These days, we have a laser welder that helps our jeweler to be able to size rings faster and more precisely. (There will be a later post on the benefits of laser welding.) However, there is still a time and a place for the time-tested torch method. Sizing Down Question: So how do we reduce the size of a ring, or size down? Jim Rogers: I first get an accurate reading of what the current size is, and if it is "out of round," [ovaled, bottom flattened, etc.] I round it out. Knowing what size to go down to allows me to gauge how much metal we are taking out. Q: Taking out? Is that how it works? J: Yes, I cut a line in the bottom of the ring, cutting out a section long enough to get to the new smaller size. Q: Then what happens? J: I carefully reshape the ring down to its new size and using solder, connect the two cut ends. I then make sure that there is no mark left where the ring was sized, as that would not be proper work if there was! Q: What about the extra piece of gold or another metal? What happens with that? J: I believe that is worked into the price of sizing down. It is usually so minuscule that it doesn't account for much. Q: Are there any issues that can come up if this isn't done properly? J: Yes - if too much solder is used and not enough of the original metal to fill it in, there can be "bubbles" left over and a mark - if there are bubbles it is called "porosity" [more on this later] and leaves a weak spot in the ring. It would be more likely to break there. Sizing Up Question: Okay, so we know how sizing down works. What about sizing up? Jim Rogers: Definitely possible. Once we know the old size and the needed size, I determine how much gold [or silver, platinum, etc.] needs to be added in. Once I know this, I can cut a spot at the bottom of the ring to add a piece in, and check if I have the right sizing piece that is a little thicker than the ring. Q: What do you mean "thicker?" What part of the ring do you mean? J: I mean the depth of the ring. Say you have a ring on and you press it to a flat surface - the distance between the surface and your finger would be the depth. Q: Why does the sizing piece have to be thicker? J: Because, after I weld [or solder] the new piece in using a combination of solder and gold [or silver/platinum], I have to file down the insert so that it is the same thickness as the rest of the ring. That way I make sure I don't leave a portion of the ring thinner than it was when it came in. And as I mentioned with sizing down, I make sure to not leave any "lines" to show that the ring was even worked on. Q: Are there any issues that can come with sizing up if not done properly? J: The same with sizing down, if the piece is not welded in right, it can break and come out. We don't do it this way, though! When to choose something other than sizingQuestion: Is there ever a time that you would NOT want to size a ring the ways you described? Jim Rogers: Yes, actually. If a ring is too thin [refer back to depth of a ring] then I do not like to size it, as we can't warranty the work. Q: No warranty on thin sizings? Why? J: When they get so thin, it's common to have bending or breaking anyway, and so we cannot guarantee that that won't happen. Q: What do you suggest instead? J: It depends on how worn down the ring is. Usually our mark is if it is under 1.0mm in depth, then we need to look at a reshank. Q: What is a reshank? J: There are two options: a half shank and a full shank. For a half shank, I cut the ring about halfway up on each side and rebuild with new gold [or silver/platinum]. For a full shank, and this is if the ring is really worn all the way up to the settings or stones on top, we cut right up to those settings and rebuild with new gold [or silver/platinum] that is thicker than before and will last for a long time. Again, we don't leave a mark. Plus, the new size of the ring is included in the price I think [it is]. Q: Back to the depth - why under 1.0mm? J: I've noticed over the years, and so have many other jewelers, that once a ring gets that thin, that is usually when we see breaking or bending of a ring - meaning it isn't holding up to everyday wear and tear like it used to [or it is supposed to]. Q: Are there issues with this, like with sizings, that can come up if not done properly? J: Same answer as the sizings - if the welds aren't done properly/with too much solder, then you can have cracks and breaks form in the future. What to expect after your ring is sizedQuestion: Are there other things that come up when you size a ring?

Jim Rogers: There can be - and most of that trouble involves loose stones. Q: Can you explain more? J: Sure. When we take a ring in, I have to get the ring surgically clean before working on it to make sure that the heat I put on it won't damage the ring [it can when there is dirt on the ring]. Many times when we get a ring in, there are already stones that are loose from wear and tear. The biggest issues usually come from sizing down. This means that all the stones in their settings on the top are "pulled," in a sense, away from their prongs a bit. This can cause stones to become loose. I do my best to make sure none get loose enough to come out in the process. Q: Okay, so if stones are loose when you're done, what happens? J: The people in the front do a "safety check" for me and then they call the customer with a quote on what it would be to tighten up the stones that are loose. Q: So this is not included in the price? J: No, because if we included it, the people we size rings for with no stones or only one or two stones would be paying for other people's stones being tightened, and we don't think that is fair. Plus, our warranty on pieces we sell and make is that we tighten stones for free for the life of the ring, as long as we're around! Q: Okay, that makes sense. Are there any other issues? J: Not usually. On closer inspection, sometimes I will find other issues with the construction of rings that we will call the customer about. I like to make sure we get the ring in the best condition possible so that in the long run, we keep the customer safe and spending the least money. Q: I've heard you say that, that it is usually less expensive to do maintenance on a piece than to have to do major replacement or repair if something breaks! J: That's right.

0 Comments

Leave a Reply. |

AuthorAssistant Manager Jenna Rogers gets the answers from our jeweler to your most important jewelry questions! Archives

February 2021

Categories |

Christmas HoursMon-Fri: 10am - 6pm

Sat: 10am - 5pm |

Phone(972) 910-0300

Call or Text |

|

Address

7750 N MacArthur Blvd #100, Irving TX 75063

|

RSS Feed

RSS Feed